Kuongorora maikorosikopu erekitironi kwakashandiswa kuona kuparara kwekuneta uye kuongorora nzira yekuputsika; panguva imwecheteyo, spin bending kuneta bvunzo yakaitwa pa decarburized samples patembiricha dzakasiyana kuenzanisa hupenyu hwekuneta kwesimbi yekuedzwa uye uye pasina decarburization, uye kuongorora mhedzisiro ye decarburization pane kuneta kuita kweyedzo simbi. Mhedzisiro yacho inoratidza kuti, nekuda kwekuvapo panguva imwe chete yeoxidation uye decarburization mukupisa, kudyidzana pakati pezviviri izvi, zvichikonzera kukora kweiyo decarburized layer nekukura kwekupisa kunoratidza maitiro ekuwedzera uye nekuderera, Ukobvu hweiyo yakazara decarburized layer inosvika pakukosha kwe120 μm pa750 ℃, uye ukobvu hweiyo decarburized layer inosvika pakukosha kushoma kwe20 μm pa850 ℃, uye muganho wekuneta wesimbi yekuyedza ungangoita 760 MPa, uye kunobva kuneta kutsemuka muyedzo simbi inonyanya Al2O3 isiri-metallic inclusions; Decarburization maitiro anoderedza zvakanyanya hupenyu hwekuneta kwesimbi yekuyedza, zvichikanganisa kushanda kwekuneta kwesimbi yekuyedza, kukora kwedecarburization layer, kudzikisa hupenyu hwekuneta. Kuti uderedze kukanganiswa kwedecarburization layer pakuita kuneta kwesimbi yekuyedza, tembiricha yekupisa yekupisa yesimbi yekuyedza inofanira kuiswa pa850 ℃.

Gear chinhu chakakosha chemotokari,nekuda kwekushanda nekumhanya kwakanyanya, iyo meshing chikamu chegiya repamusoro rinofanirwa kunge riine simba rakawanda uye kusagadzikana kweabrasion, uye mudzi wezino unofanirwa kuve nekuita kwakanaka kwekukotama kwekuneta nekuda kwekugara uchidzokororwa mutoro, kuitira kudzivirira kuputika kunotungamira kune zvinhu. kutyoka. Tsvagiridzo inoratidza kuti decarburization chinhu chakakosha chinokanganisa kupeta kuneta kuita kwesimbi zvinhu, uye spin bending kuneta kuita chiratidzo chakakosha chemhando yechigadzirwa, saka zvinodikanwa kuti udzidze maitiro e decarburization uye spin bending kuneta kuita kweyedzo zvinhu.

Mubepa rino, kupisa kupisa kwevira pane 20CrMnTi giya simbi pamusoro decarburization bvunzo, ongorora akasiyana tembiricha tembiricha pabvunzo simbi decarburization layer kudzika kwemutemo unoshanduka; uchishandisa QBWP-6000J yakapfava danda yekuyedza dhizaini yekuyedza simbi inotenderera ichikotama bvunzo yekuneta, kutsunga kwekuyedza simbi kuneta kuita, uye panguva imwe chete kuongorora kukanganiswa kwedecarburization pakuneta kwekuita kwesimbi yekuyedza kuti kugadzirwa chaiko kuve nani. maitiro ekugadzira, kuwedzera kunaka kwezvigadzirwa uye kupa inonzwisisika referensi. Iyo yekuyedza simbi yekuneta kuita inotarwa neiyo spin bending kuneta bvunzo muchina.

1. Test zvinhu uye nzira

Kuedza zvinhu zveyuniti yekupa 20CrMnTi giya simbi, iyo huru kemikari inoumbwa sezvakaratidzwa muTable 1. Decarburization bvunzo: iyo bvunzo zvinhu zvinogadziriswa mu Ф8 mm × 12 mm cylindrical specimen, iyo yepamusoro inofanira kupenya isina mavara. Imba yekupisa yekupisa yakapiswa kusvika 675 ℃, 700 ℃, 725 ℃, 750 ℃, 800 ℃, 850 ℃, 900 ℃, 950 ℃, 1,000 ℃, uye ibatisise mukamuri 1,000 ℃, uye ibatisise kumhepo. Mushure mekupisa kurapwa kwemuenzaniso nekuisa, kukuya uye kupukuta, ne 4% ye nitric acid alcohol solution kukukurwa, kushandiswa kwemetallurgical microscopy kuona test steel decarburization layer, kuyera kudzika kwedecarburization layer pane tembiricha dzakasiyana. Spin bending kuneta bvunzo: iyo bvunzo zvinhu zvinoenderana nezvinodiwa pakugadziriswa kwemapoka maviri ekupeta akapeta kuneta sampuli, boka rekutanga hariite decarburization bvunzo, boka rechipiri re decarburization bvunzo pane tembiricha dzakasiyana. Uchishandisa muchina wekuyedza kupeta kupeta, iwo mapoka maviri esimbi yekuyedza yekupeta kupeta kuneta, kutsunga kwemuganho wekuneta wemapoka maviri esimbi yekuyedza, kuenzanisa kwehupenyu hwekuneta kwemapoka maviri esimbi yekuyedza, kushandiswa kwekuongorora. erekitironi maikorosikopu kuneta kuvhunika kutarisa, ongorora zvikonzero zvekutyoka kwemuenzaniso, kuongorora mhedzisiro ye decarburization yekuneta zvimiro zveyedzo simbi.

Tafura 1 Kemikari kuumbwa (chikamu chezhinji) chesimbi yekuedzwa wt%

Mhedzisiro yekudziya tembiricha pane decarburization

Iyo morphology ye decarburization sangano pasi pekupisa kwekupisa kwakasiyana kunoratidzwa muFig. 1. Sezvinogona kuonekwa kubva pamufananidzo, kana kutonhora kuri 675 ℃, sampuli yepamusoro haioneki decarburization layer; kana tembiricha yakwira kusvika 700 ℃, iyo sample surface decarburization layer yakatanga kuoneka, kune yakaonda ferrite decarburization layer; uye tembiricha inokwira kusvika 725 ℃, iyo sampuli yepasi decarburization layer ukobvu yakawedzera zvakanyanya; 750 ℃ decarburization layer gobvu inosvika pakukosha kwayo, panguva ino, ferrite tsanga yakanyatsojeka, yakaoma; kana tembiricha yakwira kusvika 800 ℃, iyo decarburization layer ukobvu hwakatanga kudzikira zvakanyanya, ukobvu hwayo hwakadonha kusvika hafu ye750 ℃; apo tembiricha inoramba ichikwira kusvika 850 ℃ uye ukobvu hwe decarburization hunoratidzwa muFig. 1. 800 ℃, iyo yakazara decarburization layer gobvu yakatanga kuderera zvakanyanya, ukobvu hwayo hwakadonha kusvika 750 ℃ apo hafu; apo tembiricha inoramba ichikwira kusvika pa850 ℃ uye pamusoro, simbi yekuedzwa yakazara decarburization layer ukobvu inoramba ichidzikira, hafu decarburization layer ukobvu hwakatanga kuwedzera zvishoma nezvishoma kusvika iyo yakazara decarburization layer morphology yese yanyangarika, hafu decarburization layer morphology zvishoma nezvishoma kujeka. Zvinogona kuoneka kuti ukobvu hweyakazara decarburized layer pamwe nekuwedzera kwekushisa kwakatanga kuwedzera uye ndokuzoderedzwa, chikonzero chechiitiko ichi chinokonzerwa nemuenzaniso mukupisa panguva imwechete iyo oxidation uye decarburization maitiro, chete kana. iyo decarburization rate inokurumidza kupfuura kumhanya kweoxidation ichaonekwa decarburization phenomenon. Pakutanga kwekudziya, ukobvu hweiyo yakazara decarburized layer inowedzera zvishoma nezvishoma nekuwedzera kwekushisa kusvika ukobvu hweiyo decarburized layer yasvika pakukosha kwepamusoro, panguva ino kuramba ichisimudza tembiricha, chiyero che oxidation chemuenzaniso chinokurumidza kupfuura. iyo decarburization rate, iyo inodzivisa kuwedzera kweiyo yakazara decarburized layer, zvichikonzera kuderera. Zvinogona kuoneka kuti, mukati meiyo 675 ~950 ℃, kukosha kwehukobvu hweiyo yakazara decarburized layer pa750 ℃ ndiyo yakakura, uye kukosha kwehukukutu hweiyo yakazara decarburized layer pa850 ℃ ndiyo idiki, saka, kupisa kwekushisa kwesimbi yekuedza kunokurudzirwa kuva 850 ℃.

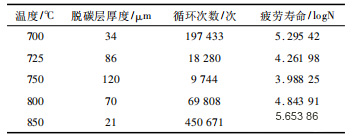

Fig.1 Histomorphology ye decarburized layer ye test steel inobatwa patembiricha dzakasiyana dzekupisa kwe1h.

Kuenzaniswa neiyo semi-decarburized layer, ukobvu hweiyo yakazara decarburized layer ine yakawedzera kuipa kukanganisa pazvinhu zvenyama, inoderedza zvakanyanya ma mechanic zvinhu zvechinhu, sekudzikisa simba, kuoma, kupfeka kuramba uye kupera simba. , nezvimwewo, uye zvakare kuwedzera kunzwisiswa kune kuputika, kunokanganisa kunaka kwewelding uye zvichingodaro. Naizvozvo, kudzora ukobvu hweiyo yakazara decarburized layer kwakakosha zvikuru kuvandudza kuita kwechigadzirwa. Mufananidzo 2 unoratidza kuchinjika kwehukubvu hweiyo yakazara decarburized layer ine tembiricha, iyo inoratidza kusiyanisa kwehupamhi hweiyo yakazara decarburized layer zvakajeka. Zvinogona kuoneka kubva pamufananidzo kuti ukobvu hweiyo yakazara decarburized layer ingori 34μm pa700 ℃; ne tembiricha ichikwira kusvika 725 ℃, ukobvu hweyakazara decarburized layer inowedzera zvakanyanya kusvika 86 μm, inodarika kaviri kukora kweiyo yakazara decarburized layer pa700 ℃; kana tembiricha yasimudzwa kusvika 750 ℃, ukobvu hweyakazara decarburized layer Kana tembiricha yakwira kusvika 750℃, ukobvu hweyakazara decarburized layer inosvika pakukosha kwe120 μm; sezvo tembiricha iri kuramba ichikwira, ukobvu hweyakazara decarburized layer hunotanga kudzikira zvakanyanya, kusvika 70 μm pa800 ℃, uyezve kusvika kune hushoma kukosha hunosvika 20μm pa850 ℃.

Fig.2 Hukobvu hwekuzara decarburized layer pane tembiricha dzakasiyana

Mhedzisiro ye decarburization pane kuneta kuita mukutenderera bending

Kuti udzidze mhedzisiro ye decarburization pane kuneta zvivakwa zvechirimo simbi, mapoka maviri epind bending kuneta bvunzo akaitwa, boka rekutanga raive kuyedza kuneta zvakananga pasina decarburization, uye boka rechipiri raive kuyedza kuneta mushure mekuita decarburization panguva imwe chete yekushushikana. level (810 MPa), uye iyo decarburization process yakaitwa pa700-850 ℃ kwe1 h. Boka rekutanga rezvienzaniso rinoratidzwa muTebhu 2, iyo ndiyo hupenyu hwekuneta kwesimbi yechirimo.

Upenyu hwekuneta hweboka rekutanga rezvienzaniso hunoratidzwa muTebhu 2. Sezvinogona kuonekwa kubva paTebhenekeri 2, pasina decarburization, simbi yekuedza yakangoiswa pasi pe 107 cycles pa810 MPa, uye hapana kuputsika kwakaitika; apo kushushikana kwepamusoro kwakapfuura 830 MPa, zvimwe zvezvienzaniso zvakatanga kuputsika; apo chiyero chekushushikana chakapfuura 850 MPa, zvienzaniso zvekuneta zvakaputsika zvose.

Tafura 2 Hupenyu hwekuneta pasi pemhando dzakasiyana dzekushushikana (pasina decarburization)

Kuti uone muganhu wekuneta, nzira yeboka inoshandiswa kugadzirisa kupera kwekuneta kwesimbi yekuedza, uye mushure mekuongorora kwenhamba ye data, kupera kwekuneta kwesimbi yekuedza inenge 760 MPa; kuitira kuti uratidze hupenyu hwekuneta kwesimbi yekuedza pasi pekunetseka kwakasiyana, iyo SN curve inorongwa, sezvinoratidzwa mumufananidzo 3. Sezvinogona kuonekwa kubva kuMufananidzo 3, maitiro akasiyana-siyana anoshungurudza anowirirana nehupenyu hwakasiyana hwekuneta, apo kuneta kwehupenyu hwe7 , inoenderana nenhamba yekutenderera kwe107, izvo zvinoreva kuti muenzaniso uri pasi pemamiriro ezvinhu aya uri kuburikidza nehurumende, iyo inoenderana yekushushikana kukosha inogona kuverengerwa sekuneta kwesimba kukosha, ndiko kuti, 760 MPa. Zvinogona kuonekwa kuti S - N curve yakakosha pakugadzirisa kwekuneta kwehupenyu hwezvinhu zvine kukosha kwakakosha.

Mufananidzo 3 SN curve yekuyedza simbi inotenderera inokotama kuneta bvunzo

Upenyu hwekuneta hweboka rechipiri remuenzaniso hunoratidzwa muTebhu 3. Sezvinogona kuonekwa kubva paTebhenekeri 3, mushure mokunge simbi yekuedza yakasvibiswa pakupisa kwakasiyana-siyana, nhamba yezvikamu zviri pachena yakaderedzwa, uye inopfuura 107, uye zvose. zvienzaniso zvekuneta zvakaputsika, uye hupenyu hwekuneta hunoderedzwa zvikuru. Yakasanganiswa neiyo pamusoro decarburized layer ukobvu pamwe netembiricha yekuchinja curve inogona kuoneka, 750 ℃ decarburized layer ukobvu ndiyo yakakura, inoenderana nekuderera kukosha kwehupenyu hwekuneta. 850 ℃ decarburized layer gobvu ndiyo idiki, inoenderana nekuneta hupenyu kukosha kwakakwira. Zvinogona kuoneka kuti decarburization maitiro anoderedza zvakanyanya kuneta kuita kwechinhu, uye iyo yakakora iyo decarburized layer, inodzikisa hupenyu hwekuneta.

Tafura 3 Hupenyu hwekuneta kune akasiyana decarburization tembiricha (560 MPa)

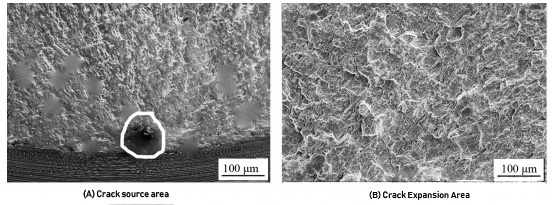

Kuneta kutyora morphology yemuenzaniso kwakaonekwa nekuongorora electron maikorosikopu, sezvakaratidzwa mumufananidzo 4. Mufananidzo 4 (a) wenzvimbo yekuputika, chimiro chinogona kuonekwa pachena kuneta arc, maererano nekuneta arc kuwana tsime. yekuneta, inogona kuonekwa, iyo crack sosi ye "hove-ziso" isiri-metallic inclusions, inclusions pane zviri nyore kukonzera kushushikana kwepfungwa, zvichiita kuti kuneta kutsemuka; Fig. 4(b) for the crack extension area morphology, inogona kuonekwa mitsetse yokuneta, yakanga yakafanana nerwizi kugovera, ndeye quasi-dissociative fracture, ine mitswe ichiwedzera, inozopedzisira yakonzera kuputsika. Mufananidzo 4(b) unoratidza morphology yenzvimbo yekuwedzera mutswe, kuneta kuri pachena kunogona kuonekwa, nenzira yekugovera-kufanana nerwizi, iyo ndeye quasi-dissociative fracture, uye nekuwedzera kunoramba kuripo kwekutsemuka, pakupedzisira kunotungamirira kukutsemuka. .

Kuneta kutyora kuongororwa

Fig.4 SEM morphology yekuneta kuputsika kwepamusoro kwesimbi yekuedza

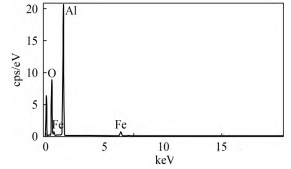

Kuti uone rudzi rwekubatanidzwa mumufananidzo 4, simba rekugadzirisa kuumbwa kwekuongorora kwakaitwa, uye zvigumisiro zvinoratidzwa mumufananidzo 5. Zvinogona kuonekwa kuti kwete-metallic inclusions inonyanya kushandiswa kweAl2O3 inclusions, zvichiratidza kuti inclusions. ndiyo inonyanya kukonzera kutsemuka kunokonzerwa ne inclusions cracking.

Mufananidzo 5 Energy Spectroscopy yeNon-metallic Inclusions

Pedzisa

(1) Kuisa tembiricha yekudziya pa850 ℃ inoderedza ukobvu hweiyo decarburized layer kuti ideredze mhedzisiro pakuita kuneta.

( 2) Muganho wekuneta weyedzo simbi inotenderera kubhenda ndeye 760 MPa.

( 3) The test steel cracking in non-metallic inclusions, kunyanya Al2O3 musanganiswa.

(4) decarburization inoderedza zvakanyanya hupenyu hwekuneta kwesimbi yekuyedza, iyo yakakora iyo decarburization layer, inodzikisa hupenyu hwekuneta.

Nguva yekutumira: Jun-21-2024